- Home

- Orthopaedic Surgery

- Knee Arthroplasty

VEGA System®

VEGA System®Posterior stabilized system for natural rotation

The posterior stabilized VEGA Knee System was developed to fulfill the modern-day requirements of patient and surgeons for a modern knee implant system. The following objectives were considered in its design:

Natural kinematics through a rollback and a pivotal motion around the medial condyle

During flexion, the natural knee shows increased rollback of the femur on the lateral side while the femur rotates around the medial center.[1] The asymmetric cam design of VEGA facilitates this lateral rollback and medial rotation, and therefore enables a natural pivotal motion.[2]

Stability even in high flexion

Based on the design and the position of the PS box and post, the contact point of the box and post move distally with an increase of flexion. Therefore the increased jumping distance in flexion can reduce the subluxation risk. The synchronized contact surfaces between the articulating components maximize the bearing surface stress distribution in extension, reducing the risk of delamination. The high congruency between femur and tibia in extension as well as the line contact up to 160° of flexion stabilizes the patient’s movements and reduces wear. To reach higher varus-valgus stability a PS+ gliding surface with a mediolaterally wider PS post is available. Posterior inclination of the post design prevents anterior impingement with the extensor mechanism and increases resistance to dislocation.

Soft tissue friendly and bone sparing implant design [2]

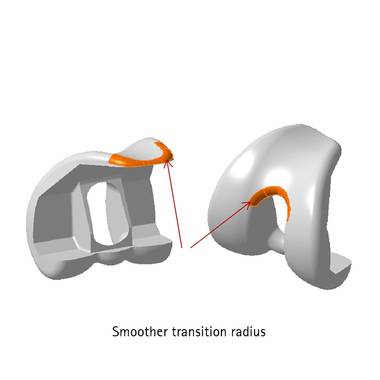

Besides the reconstruction of natural kinematics, two attributes were in the foreground during the development of the VEGA Knee System. A soft tissue friendly design as well as the reduction of bone loss. 13 femur sizes, including standard and narrow sizes, and 11 tibial sizes, including standard and AP+ sizes, offer a wide range for a better bone fit regardless of gender, size, morphotype or race. Additionally, the VEGA System®’s narrow low-profile box helps to preserve bone and results in stable patellar tracking. A short tibial stem design as well as slim tibial wings support the bone sparing philosophy of VEGA. Furthermore the curved wing design facilitates a high rotational stability.

Long-term performance through innovative materials

Advanced Surface: Wear is the number one reason for long-term knee replacement revisions.[3] To combat this issue, the AS coating can deliver up to a 65 % reduction in wear when compared to a CoCr prosthesis, as demonstrated in testing with other Aesculap knee designs. Furthermore, with the AS coating metal ion concentrations remain low and are below any biological threshold. This makes the AS coated implants an ideal solution for patients who are allergic to metal. The AS multilayer coating reduces the hardness from top to bottom in a gradient-like fashion, resulting in an improved elastic modulus. This makes it stable against mechanical stresses and strains.[4-7]

Beta Polyethylene: All of Aesculap’s polyethylenes are sterilized under Beta radiation, which reduces oxidation, decelerates the aging process, and yields better wear rates.[8-10]

Easy handling and precise results with the new generation of IQ instruments as well as the OrthoPilot® Navigation System

- Patient specific with OrthoPilot® Navigation

- User-friendly with IQ Instruments

The posterior stabilized VEGA Knee System was developed to fulfill the modern-day requirements of patient and surgeons for a modern knee implant system. The following objectives were considered in its design:

Natural kinematics through a rollback and a pivotal motion around the medial condyle

During flexion, the natural knee shows increased rollback of the femur on the lateral side while the femur rotates around the medial center.[1] The asymmetric cam design of VEGA facilitates this lateral rollback and medial rotation, and therefore enables a natural pivotal motion.[2]

Stability even in high flexion

Based on the design and the position of the PS box and post, the contact point of the box and post move distally with an increase of flexion. Therefore the increased jumping distance in flexion can reduce the subluxation risk. The synchronized contact surfaces between the articulating components maximize the bearing surface stress distribution in extension, reducing the risk of delamination. The high congruency between femur and tibia in extension as well as the line contact up to 160° of flexion stabilizes the patient’s movements and reduces wear. To reach higher varus-valgus stability a PS+ gliding surface with a mediolaterally wider PS post is available. Posterior inclination of the post design prevents anterior impingement with the extensor mechanism and increases resistance to dislocation.

Soft tissue friendly and bone sparing implant design [2]

Besides the reconstruction of natural kinematics, two attributes were in the foreground during the development of the VEGA Knee System. A soft tissue friendly design as well as the reduction of bone loss. 13 femur sizes, including standard and narrow sizes, and 11 tibial sizes, including standard and AP+ sizes, offer a wide range for a better bone fit regardless of gender, size, morphotype or race. Additionally, the VEGA System®’s narrow low-profile box helps to preserve bone and results in stable patellar tracking. A short tibial stem design as well as slim tibial wings support the bone sparing philosophy of VEGA. Furthermore the curved wing design facilitates a high rotational stability.

Long-term performance through innovative materials

Advanced Surface: Wear is the number one reason for long-term knee replacement revisions.[3] To combat this issue, the AS coating can deliver up to a 65 % reduction in wear when compared to a CoCr prosthesis, as demonstrated in testing with other Aesculap knee designs. Furthermore, with the AS coating metal ion concentrations remain low and are below any biological threshold. This makes the AS coated implants an ideal solution for patients who are allergic to metal. The AS multilayer coating reduces the hardness from top to bottom in a gradient-like fashion, resulting in an improved elastic modulus. This makes it stable against mechanical stresses and strains.[4-7]

Beta Polyethylene: All of Aesculap’s polyethylenes are sterilized under Beta radiation, which reduces oxidation, decelerates the aging process, and yields better wear rates.[8-10]

Easy handling and precise results with the new generation of IQ instruments as well as the OrthoPilot® Navigation System

- Patient specific with OrthoPilot® Navigation

- User-friendly with IQ Instruments